#Custom Metal Part Manufacturing

Explore tagged Tumblr posts

Text

Exploring Cutting-Edge Technologies in Custom Metal Part Manufacturing at Norck

Norck is a leading manufacturer in the custom metal part industry. With decades of experience under its belt, Norck has established itself as a trusted name in delivering high-quality custom metal parts to industries ranging from automotive and aerospace to medical devices and beyond.

But what sets them apart is their unwavering commitment to staying ahead of the curve when it comes to technological advancements.

At Norck, they understand embracing innovation is not just essential but also integral for survival.

They continuously push the envelope by investigating cutting-edge technologies that raise standards of quality, increase production, and ultimately provide their clients with unmatched outcomes.

Because it's so important to keep ahead of the curve in today's world, Norck is always looking for new technologies that could completely change the way metal parts are designed and made. Here, let's see some of the latest advancements in custom metal part manufacturing at Norck:

Additive Manufacturing (3D Printing)

At Norck, additive manufacturing is completely changing the Custom Metal Part production industry. Advanced technology makes it feasible to create elaborate and complicated designs that were previously unattainable with conventional manufacturing techniques.

At Norck, we make use of cutting-edge 3D printers made especially for producing metal parts. Numerous materials, including titanium, Aluminum, stainless steel, and even precious metals like gold and silver, are used in these machines. Using computer-aided design (CAD) models to direct the printer, these materials are deposited layer by layer during the process.

3D printing has a wide range of uses in custom production. It makes it possible to produce highly customized, intricately geometrized components that would be costly or difficult to create using traditional methods. Unmatched flexibility and versatility are provided by 3D printing, whether it is used for producing one-of-a-kind products or prototyping new designs.

Reducing material waste by using what is required for the particular part being created is one of 3D printing's significant benefits. When using traditional subtractive manufacturing techniques, extra material is frequently thrown during machining operations, which raises prices and has an adverse effect on the environment.

Furthermore, quick project turnaround times and iterations are made possible by 3D printing. Without the expensive tooling changes or protracted setup times connected with traditional manufacturing procedures, design updates can be easily applied.

Additive manufacturing allows for the development of lightweight structures with improved strength-to-weight ratios while also saving costs and time. Weight reduction is crucial in industries like aerospace and automotive, and optimizing internal lattice structures in printed parts allows for weight reduction without sacrificing structural integrity.

Norck is employing additive manufacturing to produce customized metal parts, which makes sense given its ability to customize, reduce waste, and increase efficiency.

The adaptability of 3D printing is one of its main benefits. It can be used in a number of industries, including consumer goods, automotive, aerospace, and medical devices. For instance, experts in the aerospace industry are using 3D printing technology to create vital, lightweight parts for aircraft engines and structures.

Custom metal part production projects benefit from 3D printing's unequaled flexibility for modification and customization. Complex designs can be easily achieved with minimal effort compared to traditional subtractive machining methods.

Automation and Robotics

The manufacturing sector has transformed because of automation and robotics, particularly in precision manufacturing. We at Norck understand that automated systems are essential to our manufacturing procedures. Robotics is a cutting-edge technology that can help us boost productivity and streamline processes.

Automation and robotics increase productivity while also improving product quality. By removing human error from repetitive operations like welding and machining, we can guarantee reliable outcomes every time. Robots reliably produce goods that satisfy tight requirements and tolerances because they perfectly obey programmed instructions.

Automation also enables us to reduce labor costs and increase production. We decrease the requirement for a large workforce on repeated operations that could otherwise be time-consuming and tiresome for human workers by depending on robotic technology for some areas of manufacturing.

Due to their exceptional accuracy and consistency in performing repeated tasks, robots are a crucial part of precision production.

One of the significant advantages of automation and robotics is the improved efficiency they bring. By implementing automated systems, production cycles can be significantly shortened as robots can work tirelessly for extended periods without fatigue or breaks.

One of the primary benefits of automation and robots is increased efficiency. With automated systems in place, production cycles can be considerably reduced because robots can work continuously for long periods without getting tired or needing breaks. That leads to faster fulfilment of custom metal part requirements, which ultimately makes customers happier.

By utilizing cutting-edge technology like automation and robots, Norck Manufacturing Company Ltd. has been able to maintain its leadership in the production of precise and high-quality custom metal parts. As we continuously work to improve our production processes, we're dedicated to investigating new developments in this area.

Advanced Materials and Material Analysis at Norck

At Norck, we are constantly pushing the boundaries of metal part manufacturing by exploring new and advanced materials. Our ability to adapt enables us to meet the unique needs of a wide range of sectors. The procedure entails the layer-by-layer deposition of material according to digital patterns, producing intricate geometries that would be very expensive or almost impossible to create with conventional techniques.

At Norck, we recognize how crucial it is to use cutting-edge materials and carry out in-depth material analyses in order to guarantee the best possible quality when creating custom metal parts. Our team analyses numerous materials used in diverse industries using state-of-the-art methods and technologies.

Regarding personalized production, 3D Printing offers numerous advantages. It not only significantly reduces material waste but also permits more design freedom. Prototyping is accelerated, and lead times for manufacturing runs are decreased. At Norck, we are dedicated to providing our clients with affordable solutions without compromising on quality or performance, which is why we are utilizing this cutting-edge technology.

Spectroscopy is one technique that does this; it analyses and identifies the constituent parts of a sample by measuring the interaction between matter and electromagnetic radiation. It helps us determine whether the product has any impurities or meets specific requirements.

We also study the composition and structure of crystals using X-ray diffraction (XRD) technology. Analyzing the interaction between X-rays and samples can reveal a lot about their physical properties, such as density, phase composition, lattice parameters, and more.

In addition to these techniques, we also use scanning electron microscopy (SEM) to obtain detailed high-magnification images of surfaces. SEM allows us to examine microstructures and surface imperfections that may affect a product's overall performance.

We also use non-destructive testing techniques; including magnetic particle inspection (MPI), eddy current testing (ECT), and ultrasonic testing (UT), to further improve our material analysis skills. By applying these techniques, we can find errors or faults without endangering the components that are being tested.

At Norck, automation, and robotics are now essential elements of precise manufacturing. Our production processes are more smoothly integrated with automated systems, which maximize accuracy while reducing human error. Robots are necessary for jobs involving repeated actions or securely moving large objects.

Numerous advantages result from automation and robotics: faster cycle times lead to increased productivity; reduced skill or fatigue variability among operators improves consistency; personnel removal from hazardous environments increases workplace safety; and so on. At Norck, we take advantage of these developments to maximize productivity along the whole value chain.

Another thing that spurs innovation at Norck is the exploration of novel materials. Our team is always looking into new materials that have better strength-to-weight ratios, resistance to corrosion, and increased thermal conductivity—all essential aspects to consider when creating high-performance metal parts for a range of uses.

Computer-Aided Design (CAD) and Simulation

At Norck, the use of computer-aided design (CAD) and simulation is essential to the production of custom metal parts. Using CAD software, details can be precisely digitally represented, facilitating effective design and prototyping. When compared to manual approaches, the capacity to see and manipulate structures in a virtual environment results in time and resource savings.

Another effective technique that Norck uses to foresee and stop possible manufacturing problems is simulation. Through the use of production process simulation, engineers can detect defects or inefficiencies in the process early on and avert costly errors later on. It lessens the need for rework or revisions throughout production, in addition to helping to ensure the quality of the final product.

In addition to preventing errors, CAD and simulation speed up design iterations. With computer-aided design (CAD), designers may experiment and make quick adjustments without having to start from scratch every time. It results in a faster development cycle overall, enabling speedier turnaround times.

An excellent illustration of how CAD and simulation have improved Norck projects is a recent customer who required a complicated, custom metal part with exacting specifications. With the use of CAD tools and simulations to evaluate several production scenarios, Norck was able to carefully design the piece and optimize its geometry for maximum performance while maintaining manufacturability within the required parameters.

The utilization of CAD software facilitates effective design iteration, while simulation helps anticipate problems prior to their occurrence. These two factors have a substantial impact on accelerating project schedules at Norck. Because these state-of-the-art technologies stop errors early in the manufacturing process, they guarantee the efficient delivery of high-quality products.

Precision Machining and Finishing

Precision is essential in the fabrication of custom metal parts. At Norck, they are aware of how crucial precision machining techniques are to producing goods of the highest caliber. They may have excellent outcomes since they use the newest technology and innovative methods.

One of the critical methods used in precision machining is Computer Numerical Control (CNC) machining. CNC machines use computer programming to control the movement of tools, resulting in highly accurate cuts and shapes. This technology allows for complex designs to be executed with exceptional precision.

Electrical discharge machining is another method used to produce outcomes with great accuracy (EDM). Tight tolerances and fine details are made possible by this procedure, which removes material from a product using electrical sparks. When working with hard materials or generating intricate shapes that would be difficult to create using conventional methods, EDM is helpful.

Apart from these methods, sophisticated measurement apparatuses are employed to guarantee precision throughout the production procedure. Coordinate Measuring Machines (CMMs) are devices that measure completed items precisely using sensors and probes. That allows for extensive quality control inspections.

But precise machining by itself isn't enough to produce superbly tailored metal parts. Precision finishing is equally significant. It is essential to ensure that the finished product is aesthetically acceptable, especially after all of the painstaking effort that goes into the machining process.

Norck uses a variety of techniques, such as grinding, polishing, sanding, and coating processes like powder coating or anodizing, since it understands the need for precise finishing. These processes improve the appearance and functionality of their distinctive metal components.

Norck invests heavily in the training of its professionals, who are skilled in utilizing these state-of-the-art mechanical systems while adhering to strict quality control protocols to create high-precision outputs through these processes consistently.

Every stage of the process at Norck, from designing with CAD software to carrying out complex cuts with accurate finishing touches, is focused on achieving perfection in the fabrication of custom metal parts by fusing cutting-edge technology with expert quality.

Sustainability and Environmental Considerations

Sustainability and environmental considerations are becoming increasingly important in the world of manufacturing. Norck is aware of this and has taken great care to reduce its influence on the environment.

Using sustainable practices throughout all of its manufacturing processes is one-way Norck does this? Every decision is made with the environment in mind, from recycling to energy conservation.

Norck guarantees that it not only satisfies industry standards but also goes above and beyond to protect the environment by implementing eco-friendly technologies and practices.

There are numerous benefits to these endeavors. To reduce expenses associated with material usage and disposal, Norck maximizes resources while minimizing waste. Not only does it help people increase their income, but it also makes everyone's future more viable.

Moreover, eco-friendly technologies typically yield higher-quality products since they are more precise and efficient. Reducing the quantity of rework or scrap materials generated during production further minimizes waste.

Furthermore, shoppers are choosing the companies they support more carefully when making purchases. By employing environmentally friendly practices, Norck enhances its reputation as a responsible manufacturer and attracts customers who share its values.

The implementation of sustainable manufacturing practices demonstrates Norck's commitment to environmental innovation and responsibility. We can anticipate even more developments in environmentally friendly solutions from businesses like Norck that work towards a greener future as technology continues to grow.

Training and Skill Development

Training and skill development are crucial aspects of operating new technologies in the field of custom metal part manufacturing. At Norck, they recognize that being abreast of the most recent developments is essential to preserving a competitive advantage in the market.

Norck has put in place a number of initiatives and programs for skill development to make sure their personnel is qualified to handle cutting-edge technologies. They offer thorough training courses that incorporate both practical and theoretical instruction. It enables staff members to get a complete grasp of how these advanced devices work and how to use them efficiently.

A key component of staying up to date with the rapidly changing trends in technology is continuous learning. Norck encourages its staff members to take advantage of possibilities for constant professional development, including online courses, seminars, and workshops. Employees may improve their abilities, keep current on industry best practices, and quickly adopt new technology by investing in continuous learning.

Technical proficiency is one of many things Norck values in its training program. By providing mentorship programs and leadership development opportunities, they also place a high priority on personal development. These courses not only give participants the technical know-how they need, but they also develop the strong leadership skills they need to encourage creativity in teams.

At every level of the company, Norck places a high priority on training and skill development to guarantee that its employees are competent in using new technology efficiently and effectively. This dedication eventually results in increased output, quality control, and customer happiness, all of which help a business keep a competitive edge in the marketplace.

Future Outlook and Innovations

Norck has an exciting and innovative future ahead of it as it keeps pushing the limits of custom metal part manufacture and technologies. The business is aware that in a field that is changing quickly, maintaining the cutting edge of technology is essential. That's why Norck places a high premium on continuing research and development.

Future technologies for the production of personalized metal parts have countless possibilities because of developments in materials science, automation, and digitalization. Norck hopes to produce intricate designs with accuracy and efficiency by employing state-of-the-art methods such as additive manufacturing (3D printing). It might completely transform production by optimizing supply chains, cutting waste, and boosting flexibility.

Norck acknowledges the significance of sustainable practices as a fundamental component of their forthcoming tactics. They seek to reduce their influence on the environment while maintaining high standards of quality in their products by embracing eco-friendly technologies and incorporating green initiatives across their operations.

Suiting oneself for upcoming industry possibilities and challenges necessitates ongoing improvement and adaptation. To provide its employees with the most up-to-date knowledge and skills necessary to use new technology successfully, Norck makes significant investments in training programs and skill development activities.

As the world continues to evolve, so does the field of custom metal part manufacturing. With advancements in technology happening at an unprecedented pace, companies like Norck need to stay ahead of the curve and embrace these innovations.

Nanotechnology is one possible future technology that might significantly affect the sector. Manufacturers can produce components with properties like improved conductivity or strength by modifying materials at the molecular level.

Another intriguing field that is making waves across industries is machine learning and artificial intelligence (AI). That is also true for the custom metal parts sector, where these state-of-the-art technologies allow for real-time data review, area identification for improvement, and even proactive maintenance predictions prior to any problems developing. AI-powered solutions hold a great deal of promise to optimize successfully.

With an eye toward the future, Norck is dedicated to maintaining the high standards of quality associated with its brand while pushing the envelope via innovation.

With a vision focused on innovation, sustainability, and skill development, Norck is well-positioned to lead the way into a thrilling future in manufacturing. By encouraging these partnerships, people can draw on outside knowledge and offer insightful commentary based on their own experiences.

Conclusion

Norck's use of these technologies has kept it at the forefront of the metal parts manufacturing business. You can put your faith in them to carry out your instructions since they are knowledgeable, trustworthy, and committed to excellence. If you're searching for a partner who can produce customized, high-quality products and who is receptive to new ideas, Norck is a perfect choice. Find out how their cutting-edge technologies and expertise may help you bring your ideas to life.

#Custom Metal Part Manufacturing#Custom Part Manufacturing#Plastic 3D printing#Custom Component Manufacturing#Advanced 3D Printing

0 notes

Text

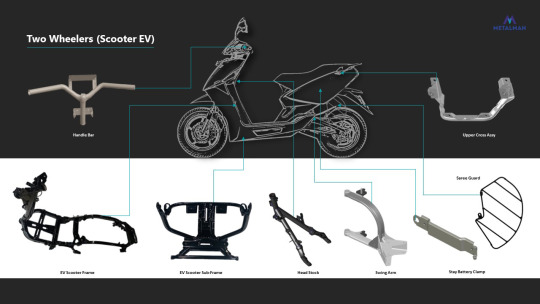

Get ready to experience Metalman Auto like never before! 🚀

Our new website is set to launch with a UI Experience and immersive 360-degree product views. This fresh digital experience is designed to showcase our strengths, capabilities, and commitment to quality in the automotive and non-automotive sectors. 🔧 What to Expect:

A sleek and modern user interface

Detailed 360-degree views of our top products

Enhanced navigation and a user-friendly experience

Comprehensive insights into our services and expertise

At Metalman Auto, we are constantly innovating to deliver excellence in metal fabrication, tubular solutions, and OEM partnerships. And now, we are bringing that innovation online! Stay tuned as we prepare to unveil a new chapter in Metalman Auto’s digital journey. Be the first to explore our innovations, discover our solutions, and connect with us like never before. 📅 Launch Date: Coming Soon! . #MetalmanAuto #AutomotiveIndustry

#automobile#automotive#car accessories#automotive parts#automotive industry#automotive tools#automotive art#vehicle#oem#oemparts#oem manufacturing#factory#heavy metal#metalman auto#Two-Wheeler Parts Manufacturer#Three-Wheeler Components Supplier#Passenger Vehicle Parts Manufacturer#Automotive Metal Components Supplier#Custom Metal Fabrication for OEM#metal fabrication#steel fabrication#fabricationservices#manufacturer#newport fabrication inc in canada#supplier#Electric Vehicle (EV) Parts Supplier#electric vehicles#hyundai#evs#electric car

2 notes

·

View notes

Text

Custom Metal Part Finishing: A Comprehensive Guide

Custom metal parts play an integral role in many industries, including automotive, aerospace, medical, and consumer goods. Machining alone may not fulfill all functional or aesthetic requirements in these fields; thus custom metal part finishing becomes crucial. We will examine its key aspects, the most popular techniques available today, and how you can select an effective process that meets your individual requirements in this article.

Custom Metal Part Finishing

Custom metal part finishing refers to post-production processes applied post-manufacturing that aim to enhance appearance, functionality, and durability of manufactured parts. Such techniques ensure parts meet stringent industry standards while withstanding environmental stresses; finishing may include polishing, coating, texturing or any other surface treatments designed to optimize metal properties.

Popular Metal Part Finishing Techniques

1. Anodizing

Anodizing creates a protective oxide layer on metal surfaces, typically aluminum, to increase corrosion resistance while adding aesthetic options through coloring options and aesthetic aesthetics.

2. Powder Coating

Powder coating involves creating a durable and high-quality finish using electrostatic spray deposition technology to apply an elegant yet protective finish that resists chipping, fading and scratching. It has become one of the most sought-after coating methods.

3. Electroplating

Electroplating deposits a thin coating of metal such as chrome or nickel onto the surface of an object to increase wear resistance, conductivity, and aesthetic appeal.

4. PVD Coating (Physical Vapor Deposition)

PVD coating provides an ultra-thin and hard coating with superior surface durability and modern aesthetic appeal, making it suitable for applications demanding both performance and aesthetics.

5. Polishing

Polishing smooths metal surfaces to increase their shine while decreasing friction. It is widely utilized by industries like medical devices and consumer electronics for its high-gloss effect.

6. Brushing

A brushed finish adds texture, concealing scratches while giving a sophisticated appearance - often used for decorative applications.

Why Finishing Matters for Custom Metal Parts

1. Improved Corrosion Resistance

Various finishing techniques, such as anodizing or powder coating, create a barrier against moisture, chemicals, and oxidation which reduces corrosion risk while prolonging product lifespan.

2. Improved Durability

Finishing processes increase surface hardness and resistance to wear, which reduces maintenance costs and ensures reliable performance.

3. Aesthetic Appeal

The perfect finish can make any metal part visually striking and customizable options are limitless when it comes to aesthetic appeal. From matte finishes to mirror-like surfaces, customization options abound.

4. Functional Upgrades

Finishes like electroplating enhance conductivity while texturing can increase grip or decrease friction for specific applications.

How to Select the Appropriate Custom Metal Part Finishing Process

Selecting the appropriate finishing process depends on several key considerations: Materials: Make sure the finishing technique you select complements your metal substrate - anodizing may work better on aluminum while PVD may suit stainless steel better.

Industry Requirements: Certain industries may require special finishes; for instance, medical devices often necessitate polished biocompatible surfaces.

Environment: When selecting a protective finish for an operating environment such as moisture exposure, temperature fluctuation or chemicals, consider your environment carefully to select an ideal protective coating solution. Budget: Some finishes such as powder coating are cost-effective while more sophisticated solutions such as PVD may require greater investment.

Applications of Custom Metal Part Finishing

1. Automotive Sector

From decorative trims to functional engine components, finishes such as electroplating and powder coating ensure both durability and style in this sector of industry.

2. Aerospace Industry

Lightweight and corrosion-resistant coatings are essential in parts exposed to high altitudes and extreme environments.

3. Medical Devices

Polished and biocompatible finishes enhance the usability and safety of surgical tools and implants, increasing their usability while simultaneously increasing safety.

4. Consumer Electronics

Brushed or anodized finishes offer a sleek aesthetic in devices like smartphones and laptops.

Future of Custom Metal Part Finishing Services

Advances in finishing technology such as eco-friendly coatings and 3D surface texturing have enabled more eco-friendly and sustainable solutions, giving manufacturers access to superior performance while simultaneously minimizing their environmental footprint.

Custom metal part finishing is an integral step in the production process, helping parts meet industry standards while meeting customer expectations. By understanding available techniques and their applications, manufacturers can ensure their products satisfy both standards and customers. No matter whether it's automotive, aerospace or consumer goods - having the appropriate finish can make a world of difference in performance, appearance and durability.

#cnc machining service#Custom metal part#Custom Metal Part Finishing#Custom CNC Parts#CNC parts manufacturing

0 notes

Text

#custom heavy vehicle parts#truck components#bus parts#custom metal fabrication#OEM metal parts.#OEM truck parts#vehicle components#metal fabrication#truck parts manufacturer#heavy vehicle parts supplier.

0 notes

Text

"The Role of Custom Sheet Metal Parts in Atlanta's Growing Tech Industry"

As Atlanta continues to establish itself as a leading hub for technology and innovation, the demand for precision-engineered components is soaring. One critical area contributing to this growth is the production of Custom sheet metal parts manufacturer in atlanta. With its unique combination of design flexibility, durability, and cost-effectiveness, custom sheet metal fabrication plays an essential role in the tech sector.

Meeting Diverse Industry Needs

Atlanta's tech industry encompasses a wide range of sectors, including telecommunications, aerospace, and medical devices. Each of these fields requires specialized components tailored to their specific needs. Custom sheet metal parts can be designed to meet stringent specifications, ensuring that they align perfectly with the requirements of complex systems and devices.

For instance, in the telecommunications sector, companies often need custom enclosures for electronic equipment. These enclosures must not only provide protection but also facilitate efficient heat dissipation and signal transmission. A custom sheet metal parts manufacturer in Atlanta like Perfect Precision Products can develop enclosures that meet these criteria, ensuring optimal performance and longevity.

Enhancing Product Performance

The use of custom sheet metal parts allows tech companies to enhance the overall performance of their products. High-quality sheet metal components can improve structural integrity and weight distribution, which is particularly crucial in industries such as aerospace, where every ounce counts. Moreover, custom parts can be designed to accommodate advanced technologies, such as integrated cooling systems for high-performance electronics.

Perfect Precision Products, a leading custom sheet metal parts manufacturer in Atlanta, leverages advanced technologies and skilled craftsmanship to create parts that meet the highest quality standards. This commitment to excellence helps local tech companies maintain their competitive edge in the fast-paced market.

Streamlining Production Processes

In the rapidly evolving tech landscape, speed and efficiency are vital. Custom sheet metal fabrication allows for streamlined production processes, reducing lead times and ensuring timely delivery of components. This flexibility is essential for tech companies that need to adapt quickly to market demands and technological advancements.

By partnering with a reliable custom sheet metal parts manufacturer like Perfect Precision Products, businesses in Atlanta can benefit from a smooth supply chain and responsive production capabilities. This partnership enables tech companies to focus on innovation and product development rather than worrying about component sourcing and manufacturing challenges.

Sustainability and Cost-Effectiveness

As companies increasingly prioritize sustainability, custom sheet metal parts can play a pivotal role in reducing environmental impact. Sheet metal is highly recyclable, and using custom parts can lead to less waste during production. Additionally, advancements in manufacturing technologies have made it possible to produce these parts with greater efficiency, lowering costs and minimizing resource consumption.

Perfect Precision Products is dedicated to sustainable practices, ensuring that their manufacturing processes are environmentally friendly while maintaining affordability for their clients.

Conclusion

The role of custom sheet metal parts in Atlanta's growing tech industry cannot be overstated. As technology continues to advance and diversify, the need for high-quality, custom-engineered components will only increase. By partnering with experienced manufacturers like Perfect Precision Products, tech companies can ensure they have the right parts to drive innovation and success. With a focus on quality, efficiency, and sustainability, custom sheet metal fabrication is set to remain a cornerstone of Atlanta's thriving tech landscape.

perfectprecisionproducts is India's leading manufacturer of Custom sheet metal parts manufacturer in atlanta. You can contact them for further information regarding the Custom sheet metal parts manufacturer in atlanta

0 notes

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Top Reasons To Choose The Cut Profiled Rubber Parts

Rubber is a widely used material that is suitable for numerous uses and industries due to its unique properties. Cut profiled rubber parts and rubber gaskets are well-known crucial parts of many machines and devices.

The cut profiled rubber parts are light in weight, have elasticity, and are capable of withstanding high impact and shock or vibration. Thus, cut rubber profiles are suitable for use as seals, bumpers, rollers, and wear pads on various pieces of construction equipment. The technical benefit of customizing a certain rubber piece is the potential to trim the rubber according to the shape necessary for a particular application. Tight tolerance cutting ensures that such components as molded rubber grommets pass-through holes and fit tightly to avoid leakage.

The Cut Profiled Rubber Parts And It's Top Hidden Benefits

Rubber gaskets for custom applications have the properties of a high compression set, as well as good recovery. It also guarantees that there is an excellent fit over time regardless of the temperatures inside or outside the car, vibrations, or number of cycles of assembly/disassembly. You should definitely go for the best cut profiled rubber parts or rubber gasket cutting if you are looking for top experience.

Top Hidden Facts About The Rubber Gasket Cutting That You Must Know

It is much cheaper to make cut-profiled rubber parts or gaskets as compared to those made from metal or plastics. It also uses less energy and generates less waste compared to other methods of food preparation. Rubber part fabrication reduces the requirements for other processes in the manufacturing process such as coating paint, or finishing. The precision cutting of rubber profiles and gaskets results in easier installation, improved performance of parts, longer use life and the minimum cost. Go ahead! Claim the top benefits of the impeccable cut profiled rubber parts and rubber gasket cutting for the most amazing experience.

#cut profiled rubber#rubber gasket cutting#custom rubber cutting services#rubber bonding to metal manufacturer#Polyurethane rubber part

0 notes

Text

Brass CNC Turned Parts and Components Manufacturer in India

GK Metals is Jamnagar, India based manufacturer, supplier and exporter of high-quality customized brass CNC turned parts, brass CNC turned components and brass CNC machining parts with great precision & accuracy. Our CNC turned parts are made from brass, copper, bronze and stainless steel materials.

#brass cnc turned parts#brass cnc turned components#brass cnc machining parts#customized brass cnc turned parts#brass cnc turned parts manufacturers#brass cnc turned components manufacturers#brass#brass parts#brass components#gk metals

0 notes

Text

some thoughts about Clothes For Horses

out of practicality the average ironwall citizen wears a blanket made for horses (even if they are not horses). the blankets are bulk-ordered by specialist ironwall tailor shops and modified on the premises, sometimes while the customer is waiting. the modifications lengthen the straps so that they can be easily reached. this is considered okay for casualwear but tacky for formal occasions.

the upper body can usually just wear whatever mass produced human clothing they like. the only item of clothing which is made specifically for these guys is the waist sash (sometimes with an additional cloth drape on the front, which can smarten up an outfit). these are people whose culture has a deep seam of embarrassment at being part animal, and this fact should be hidden if at all possible even though it isn't possible but you just have to try. the junction between fur and skin is always hidden. the orange blanket pictured above is about as skimpy as you could get away with in public. mane hair is usually shaved off for practicality's sake.

for practical work where harnesses and tack are required, these are usually worn over blankets and modified to include no reins/other control apparatus. for those for whom it is possible, horse-shoes are worn on the front feet for daily city life, and on all feet for hard manual labour or any activities/hobbies/etc which require good traction on the hind legs. shoes are usually not made of metal but of a composite into which grip studs can be inserted if necessary. the imagery of hard metal shoes is associated with counterculture movements and sometimes if you wanna look hard you can have your shoes spraypainted to be shiny. barefoot is actually fine in most circumstances

dedicated centaur clothing is stupid expensive because very few manufacturers produce it and the fabric yardage is insane so it is a class signifier. the garment shape & purpose is unisex though due to influence from dominant human cultures in the area, there's still a difference between a Stallion's Manly Robes and a Demure Filly Dress. ideally the full body is covered and the overall impression is of a human strapped to some mysterious shape idk what could possibly be under there. normal human legs i bet.

1K notes

·

View notes

Text

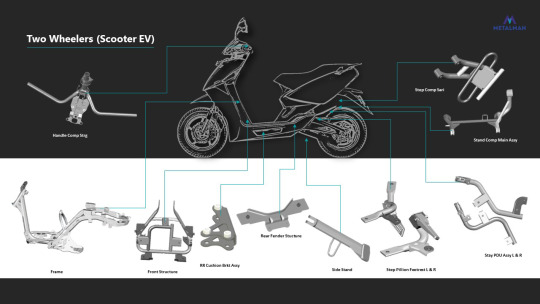

Elevate Your Vision with Metalman Auto Limited

🔧 Our product range drives industries worldwide, from Two-Wheeler assemblies to Commercial and Heavy vehicle components. With decades of expertise, we deliver innovative, high-quality metal fabrications that set the benchmark in the automotive and non-automotive sectors.

🚗 Automotive Mastery: Our cutting-edge capabilities include sheet metal parts, tubular assemblies, and fabricated components, powering passenger vehicles, commercial vehicles, and the fast-evolving EV segment with unmatched reliability.

🏗️ Beyond Automotive: Our versatility shines in industrial machinery, construction equipment, and agriculture, where we create bespoke solutions designed for demanding applications and unique manufacturing challenges.

📍 Backed by 12 advanced facilities, in-house surface finishing like ACED painting and powder coating, and globally recognized certifications (IATF 16949:2016, ISO 14001:2015, OHSAS 18001:2007), we combine innovation, sustainability, and precision to deliver results you can trust.

🌍 Partner with us and let innovation meet durability in your next project.

👉 Swipe to explore our full range of solutions!

📞 Contact us: +91-9700969700 | Email: [email protected]

🌐 Visit us: www.metalmanauto.com

#Two Wheeler Parts Manufacturer#Two Wheeler Manufacturer#automotive parts#metal fabrication#automotive#fabricationservices#electric car parts manufacturer#oem manufacturing#metalman auto#electric vehicles#components manufacturers#metal parts manufacturer#manufacturers#manufacturing#custom metal parts manufacturer for oems

0 notes

Text

Best OEM Automotive Parts Supplier | Metalman Auto Ltd

We Are the Best OEM Automotive Parts Supplier: Excellence in Every Component Metalman Auto Ltd. is the best OEM automotive parts supplier due to our unmatchable quality. Our pioneering efforts in excellence and customer satisfaction have made us the top choice for a variety of Original Equipment Manufacturers and vehicles. In addition to 2Ws, which include EVs and ICE two-wheelers, the same is true for 3Ws, PVs, CVs, AVs, and OHVs. Moreover, we are masters in producing components that suit to white body goods, and we are excellent in contract manufacturing part of the eco-system for 2W EV OEMs. Cutting-Edge Technology for Superior Products We use cutting-edge technology to make top-quality automotive parts in Metalman Auto Ltd. Our cutting-edge manufacturing facilities are equipped with specialized machinery and the latest state-of-the-art equipment; these devices are designed to allow us to produce complex components to close tolerances, exactly matching the needs of all OEMs. To achieve exceptional accuracy and dependability, we integrate CNC devices, our in-house robotic, and modern manufacturing. Our robot is designed to conduct intricate welding and metal forming tasks; greater control power is used to rule-out human error, reduce waste, and make more precise finished goods.

Quality Assurance tools, AI and Machine Learning

We are building quality. We use AI and automation in the manufacturing process to ensure every produced part meets our high standards. Our AI system checks the production in the best case in real time and makes a look whether there are defects or inconsistent results that disqualifies the product. Through use of these advanced algorithms that analyze data from many points throughout the manufacturing process, we can diagnose and fix problems before they rear their heads in finished parts.

Besides quality checks, our AI software is also optimizing the finishing processes for us. Such tasks include polishing, coating and painting all the parts to make sure not only will they work as intended but also look good doing it. We can do this while focusing on processes that will deliver end results of lasting, more aesthetically-pleasing products with a protective coating built in.

Devotion to Innovation and Incremental Improvement

Innovation is the key to stay best OEM auto parts manufacturers, as we think at Metalman Auto Ltd. Our team is always on the prowl for cutting edge technology and new innovative methods to incorporate into our manufacturing processes. This involves incorporating the latest metal finishing equipment and techniques to improve the quality of our components, in terms of their performance and aesthetics.

We also appreciate the need to avoid complacency in our quest for greatness. Our team of engineers and technicians are continuously working to perfect our processes, reducing lead times and improving the efficiency across all aspects of operations. With a culture of innovation and building to continually improve, high-quality products are being released from us.

Our Valued Clients

Over the years, we have been able to work with some of the biggest names in automotive and industrial. Our clients are Hero, TVS, Gogoro and more from the Manufacturer side & Mahindra Electric| Honda Motorcycle | Ather Energy | Bajaj Auto CNH Industrial Epiroc JCB LiuGong Normet Sumitomo Riko Group Michelin Camso etc. These relationships underscore our dedication to quality, dependability and customer service as well the offering of premium products that cater to a variety of industry needs.

Various Automotive and Industrial Use Cases

We offer a wide range of components that are suitable for diverse vehicle types. We cater from the smaller two-wheeler parts (electric and ICE) to three wheelers, passenger vehicles, commercial vehicles, agri-vehicles and off-highway vehicles. Besides, we are experienced in white goods cosmetic part fabrication like washing machine front and rear panels and back covers so as to offer an extensive application field.

Why Metalman Auto Ltd. For OEM Automotive Parts?

When you source your aftermarket car parts from Metalman Auto Ltd., you are sure to be working with an OEM automotive manufacturer that prioritizes quality, innovation and customer satisfaction above all else. With how much we have been doing with cutting edge technology and never settling for less of a product when it comes to performance, the portfolio is well tailored to meet OEM demands from automotive or the industrial sector.

Please feel free to get in touch with us as soon as possible for more information regarding our automotive parts manufacturing capabilities and how we can provide your business with the highest quality components which are engineered tough enough to manage even punishing conditions.

#archaeology#astrophotography#auspol#OEM Automotive Parts Supplier#Two-Wheeler Parts Manufacturer#Three-Wheeler Components Supplier#Passenger Vehicle Parts Manufacturer#Commercial Vehicle Parts Supplier#Agri-Vehicle Components Manufacturer#Off-Highway Vehicle Parts Supplier#B2B Automotive Parts Supply Chain#Custom Metal Fabrication for OEMs#Automotive Metal Components Supplier#Precision Tubular Fabrication Services#Metal Finishing for Automotive Parts#High-Volume Automotive Parts Manufacturing#Contract Manufacturing for Vehicle OEMs#Automotive Parts Manufacturing in India#Heavy-Duty Vehicle Parts Manufacturer#Electric Vehicle (EV) Parts Supplier#Supply Chain Solutions for Auto OEMs#Industrial Metal Fabrication Services#Automotive Assembly Parts Manufacturer#metal parts components#india automotive components manufacturer#automotive components#vintage automobiles#automotive#autogynephilia#automobile

1 note

·

View note

Text

Battle Jacket Tips! Yippee!!

I'm hyperfixating, so be warned that this might be rambly and a lot longer than it needs to be, but I promise these are good tips

I'll try to put all my rambles in small text and if it gets too long, I'll stick it under a read-more-- oh, would you look at that

For starters, what is a battle jacket? Maybe you've just stumbled across this post and have no context, or maybe you're researching bc you think you might be interested in making one, here's a short explanation:

Battle jackets are a popular garment in a lot of alternative communities. Punk and metal are the biggest two that I'll be focusing on, but there's genuinely no limit to the "genres" that a battle jacket could belong to. I don't like country music, but like, if you want to make a country battle jacket, do it! Have fun!

Battle jackets are typically either leather or denim and covered in patches and pins to the wearer's taste. Punk battle jackets might include more political sentiments and DIY than say, a metal battle jacket, but of course, there are no rules, and my battle jackets tend to be a bit of a mix of punk and metal. Remember: There are no rules, these are all just suggestions.

The Base:

A few suggestions for your first battle jacket:

Do thrift your starting garment. If you can't find something exactly like what you're looking for, don't sweat it. Find something "good enough" and get started. That's what fabric dye and scissors are for. DIY or Die is the motto here. My most recent battle vest started life blue and with sleeves. Now it's black with big yellow panels in the sides.

Do get your jacket a little bigger than usual. Patches can stiffen up the garment and make it feel tighter, plus, if you wear it year round you'll wanna be able to put it over your coat in the colder season. I actually have two vests, a warm weather and a cold weather vest. The warm weather vest is a lot smaller so it doesn't hang off me when I'm just wearing a shirt, but I recommend starting with a larger vest and doing the "warm weather" vest as a second project.

Don't buy a premade battle jacket, especially fast fashion. The whole point is to make it to your tastes, so buying a jacket with someone else's patches and pin picks kinda mucks up the best parts of making a unique, custom garment. Also, the fast fashion industry is horrifically exploitative, and supporting it financially isn't very punk. If you've already done so, don't beat yourself up. We're all learning and growing. Take the things you learn and grow from them in the future. That is punk.

The Patches:

The biggest patch on a battle jacket is your "back patch." They're huge and seen as the sort of "keystone" of a jacket. They're not a requirement, but I like them a lot. Usually, the patch is of the wearer's favorite album, or something similar, but they can be anything you want. Tarot cards, art pieces. Go nuts and find something that brings you joy. My first vest was very "traditional" with a Metallica Master of Puppets patch, but my second one has painted + embroidered handprints from all my long-distance friends so I can keep them with me <3

Do buy directly from band websites, or from the merch stands at live shows! That's my favorite way to get patches, even if they might be expensive or have iffy manufacturing ethics because it shows where my vest has been and what it's seen.

Do buy from small businesses and online vendors. Try your local craft fairs, or Etsy shops for patches you like. They might be pricier, but that's just because the seller isn't exploiting factory workers and valuing their own time.

Do make your own patches! I might go more into this later, or on a different post, but there are a lot of ways to make your own patches. Embroidery, paint, stenciling, etc. You can get fabric quarters at most craft supply places for like $3 USD tops or free if there's a local Hobby Lobby. Acrylic paint works, though it might crack a bit over time. Fabric paint is pretty widely available and gives a smoother look.

Don't just buy wholesale packs of patches on Amazon. Like the above point about premade jackets, bulk patch packs are often made in exploitative sweatshop conditions, and Amazon should be used sparingly because even if the manufacturer is ethical, Amazon's warehouses are not. Also like the above, don't beat yourself up if you already bought a pack of patches. I did it too, when I first started, you live and you learn.

Don't wear patches for bands you don't know. I mean, you can, I'm not a cop, but you will look like a poser.

Non-Patch Editions:

I said it before, and I'll say it again. There are no rules. You don't have to limit yourself just to patches to customize your jacket. Have fun with it. Here's a list of options to give you ideas, based on things that I've done or want to do on my own.

Embroider directly on the fabric! I put spider webs and violets on my vests just because I like them and think embroidery is fun.

Spikes and studs!! You can get packs of spikes from lots of places (some more ethically than others) or you can make your own. As a disclaimer, some music venues may raise issues with pointier bits, as they could cause injury to other people, so use your best judgment.

Add other metal bits! Can tabs, lighter hoods, chains, keys, washers, nails, bolts, and pieces of scrap metal are all pretty fun to play around with!

Corsetting. Whether as a resizing measure or just for the aesthetic, get some eyelets and throw some ribbon in there. Could be fun!

Pins! I've mentioned them before, but also you can make your own with some bottle caps and a safety pin. Or repaint buttons you already have. I've kept the same little pronoun pin I repainted with nail polish for almost a decade, and it's still in great shape.

Putting it all together:

These are some general tips for putting all the pieces together, and honestly was supposed to be the whole post, but I like to talk so here we go!!

Lay out everything first before sewing it down. I have ripped up more patches than I care to admit, just to sew them back down on another part of the jacket.

Big tip for the mix-patch crowds, keep all your political patches on the front of the jacket. The idea is, if some asshole has a problem with your opinions, you want to see them coming. You don't want them sneaking up behind you.

Thread. Elder Punks often recommend dental floss for fastening patches to your jacket bc of its strength and rightfully sew (hahaha!). However, if you'd like more colorful options, try upholstery thread. It's super strong, and it's what I use on all of my own jackets. Though, I do keep floss and a needle around for convenient repairs. The box has its own thread cutter!

Needles. If you're like me and have shitty old person hands at the ripe old age of 23, those tiny dollar store needles will make your hands cramp up like a motherfucker. For this reason, I use doll needles. My default needle came in a walmart pack, and I use the smallest gauge, 3 in long needle. The thicker ones are too hard to get through the fabric. It's much easier to grab and easier on my hands.

Thimbles. Even with big-ass doll needles, sometimes it's difficult to grab them well enough to get through really thick fabrics. That's what thimbles are for (not to keep you from pricking yourself with the sharp end). Get yourself one, or improvise something similar, it will save your life.

Stitching. Sew down all of your patches, even the ones that claim to be "iron-on" because in my experience the iron-on adhesive fails pretty quickly. I recommend a whip or blanket stitch, so the edges don't peel up or fray (as handmade patches might). If you're moshing, a lot of folks claim that floss is best because it keeps people from ripping off your patches. Respectfully, I think that's a bunch of horseshit. If you don't want your patches ripped off, make them harder to grab onto. Keep your stitches small and close together so assholes can't get a grip on them. That said, I've never actually had someone try to rip off my patches in the pit or otherwise, so use your own discretion.

Washing. A lot of hardcore crust punks will tell you never to wash your battle jacket, but crust punk isn't for everyone. I wash my jacket every year or so, and it's pretty easy to do as long as nothing on your vest is susceptible to damage in water (I had some early patches that I finished with Modpodge that were ruined in the first wash, so keep that in mind). If you're confident in your stitchwork, just toss the vest in a garment washing bag or a pillowcase and chuck it in the wash with everything else. If you're a little more cautious, it's easy enough to hand wash it in a tub/sink and hang it out to dry. Don't use bleach or you'll probably ruin something.

21 notes

·

View notes

Text

Novel etching technique enhances absorptivity of powders for metal 3D-printing

In a significant advancement for metal additive manufacturing, researchers at Lawrence Livermore National Laboratory (LLNL) and their academic partners have developed a technique that enhances the optical absorptivity of metal powders used in 3D printing. The approach, which involves creating nanoscale surface features on metal powders, promises to improve the efficiency and quality of printed metal parts, particularly for challenging materials like copper and tungsten, according to researchers. Additive manufacturing (AM)—more commonly known as 3D printing—has transformed the way products are designed and produced, allowing for the creation of complex geometries and customized components that traditional manufacturing methods struggle to achieve.

Read more.

#Materials Science#Science#Powder#3D printing#Additive manufacturing#Etching#Absorptivity#Metals#Copper

13 notes

·

View notes

Text

What I think disability aids made by Borderlands gun manufacturers would be like. CW for mentions of systemic ableism and weight loss.

Atlas: Sleek and fancy, but also expensive as hell and prone to accidents. Sort of like IRL fancy prostheses or wheelchairs - they seem cool but are actually kinda sucky and very pricey. Don't expect the average Promethean to afford one. Though in this case, it's because they're often loaded with purely experimental tech that was probably shipped too early.

Hyperion: They make a few prosthetic and implant models and that's it. Pretty much all their stuff is aimed at their own employees trying to get "ahead" and not actual disabled people, so give up trying to find one fitting your particular needs. At least they're pretty fucking sturdy (but not against hacking). And no, they haven't thought of adopting those exoskeletons their engineers use for other needs.

Maliwan: Similar to above, but aimed at their general customer base instead. These guys are hipsters who try marrying form and function, and in many cases that means augs of some sort. I wouldn't really call them transhumanist though, that implies respecting bodily autonomy, human rights and not being ableist; these guys would sell arms with tracking chips and neural interfaces that fry your brainstem if you don't pay the subscription fee. And then tell you to lose weight with the new fad diet their marketing department cooked up. The hoverchairs and flavored chewelry are pretty great, tho.

Dahl: They wouldn't. They claim to be reliable but they're actually the biggest cowards in the Six Galaxies. If one of their soldiers loses a leg or something that's grounds for being (dis)honorably discharged. What exoskeletons or other devices they make are purely for war. Plus, the one Dahl employee we see having a prosthesis (Helena Pierce) doesn't seem to have a Dahl brand one. Aside from weird metal rank implants and funky gun-inspired fidget cubes they don't do much in this department.

Torgue: Expect everything to be painted like a Hot Wheels toy and probably explode somehow - either on you or on your enemies. All the mobility aids have jets attached for either smacking ableists with great force or speeding through town. I think Torgue himself wears a hearing aid (from all the explosions) and it looks like a fucking microphone with car parts on it, complete with exhaust.

Jakobs: Steampunk baybeee!!! Of course, the subgenre of said steampunk depends on the quality of the aid. The most basic ones are IRL Victorian era metal arms: flat, spiky, inhuman, but still quite ornate. The ones custom-tooled for execs and their families (looking at you, Alistair Hammerlock) are more "sleek" steampunk, with fine chassis of signature Jakobs brass and filigree engravings. They also make genuine wood canes with organic rubber grips that will outlive you if you take proper care of them... which is definitely shown in their price tags. The Jakobs stim toy line is half weird gear contraptions, half competition with Dahl's fidget cubes.

Vladof: Heavy, clunky, dieselpunk style. But damn if they aren't effective. A standard Vladof boostchair could break through a wall and be completely unharmed. A Vladof AAC device looks like an electron tube supercomputer that you have to haul around in a cart. That's all I really have to say here.

Tediore: I have no idea.

59 notes

·

View notes

Text

so I think we can all agree the retcon that matoran gender distribution was the result of the great beings being stupid and terrible wasn't that well thought out. Here's what I think would have been a more interesting alternative; vortixx cultural export

vortixx have a misandrist society and are a massive source of trade in the MU, so likely when sorting out how matoran (a genderless species) fit into their society they would distribute male/female based on what each type does, with matoran types you want to keep in good graces being dubbed female and matoran you want to keep in their station (or don't live there) dubbed male

female;

ga matoran would likely be important to handling ships and transportation, which is pretty important if you want to run a country based on heavy exporting

vo matoran would likely be electrical workers or handle electronics production and manufacturing, which are important to a high-tech industrial economy

ce matoran would probably be in-house therapists (good for keeping workers happy or at least from striking or going crazy) and maybe customer service. Someone to manage customers and internal problems would be important for a corporate structure

(given their importance, this might mean the vortixx see the nynrah ghosts as female)

male;

ta, fe, and su matoran would likely be mostly be used in metal working and maintaining components that get really hot (intentionally or not)

le matoran would likely find xia uninhabitable due to all the polluted air and the lifestyle there being incompatible with adventure (best explanation I can come up with for le matoran not also being used for shipping)

po, onu, and ba matoran would mostly be used for construction or repairs

ko matoran would probably be data ntry if they exist there at all

fa matoran (I can't think of a reason they wouldn't be in shipping, I genuinely can't think of an answer here)

bo matoran would probably find the place uninhabitable due to the heavy pollution and vast lack of plants

de matoran can barely handle whistling, so a whole isnand of loud manufacturing and constant talking would make xia a second karzahni to them

av matoran;

av matoran in canon can be male or female. my explanation is either someone noticed all the female matoran were blue and av-matoran can color shift themselves or it's a debate on them being able to use their element vs. them probably not living on xia

Now for the fun part: why is this idea of matoran gender distribution so widespread? pridak. pridak controlled xia during the league of 6 kingdoms, specifically because they were the biggest distributor of weapons, meaning the 6 kingdoms (which ruled most of the MU and had trade agreements with metru nui) were receiving frequent imports from xia and what comes along trade routes? cultural ideas. Likely, the vortixx's idea of how to define matoran among their own cultural ideas spread without the context of industrial use.

how/if their ideas spread to the other sapient species of the MU is unclear, but they may have had their own ideas

and that is my attempt to provide a more satisfying answer to a not very well thought out plotpoint

4 notes

·

View notes

Text

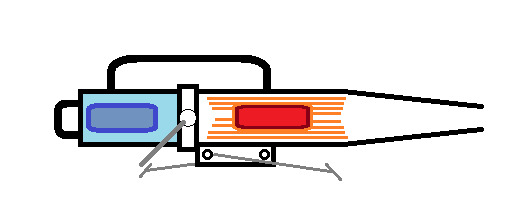

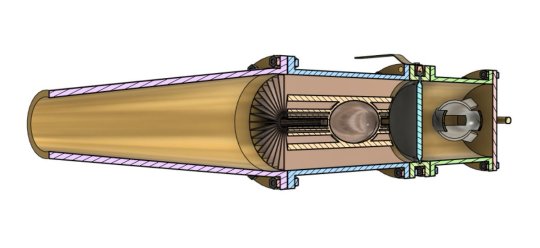

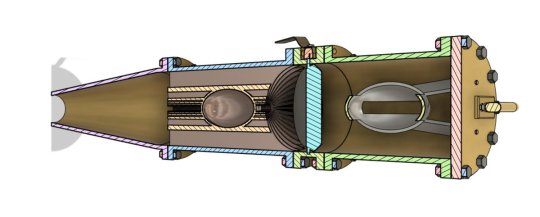

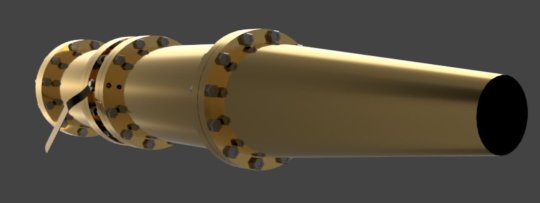

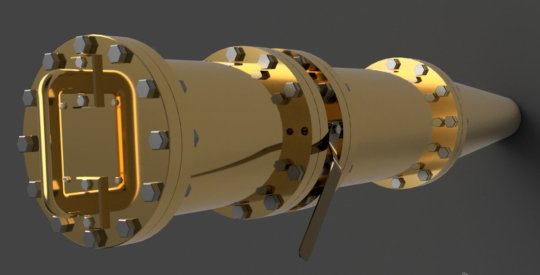

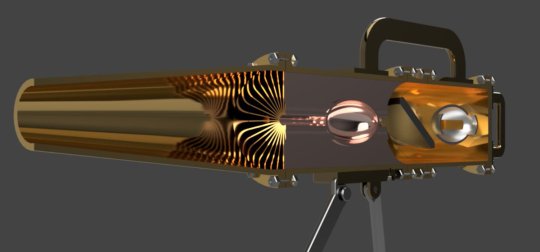

it all started rather innocently. we just found two magical rocks in our d&d campaign - one that produces heat, and another that creates water. my character (well, okay, my character was a warlock and not an artificer, so it was mostly me, really) put two and two together and figured out that this may be used as an infinite source of steam. tech level of our campaign allowed us to manufacture or commission custom parts made of metals like bronze, copper, platinum, et cetera. and so, shenanigans ensued. out of character, i devised a contraption that would shoot a blast of steam and parboil anything that stands in front of it. war crimes, yay!

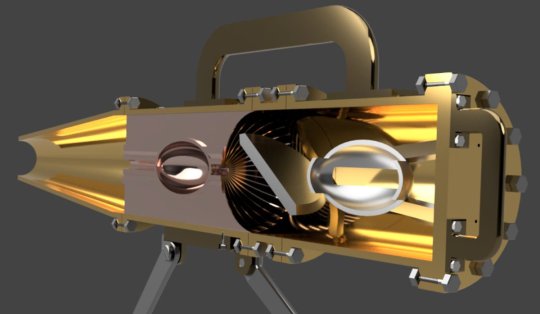

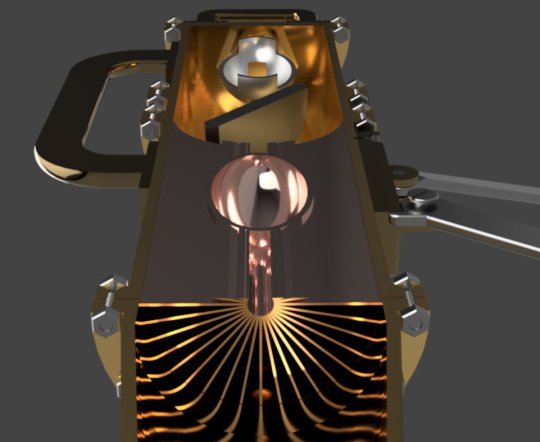

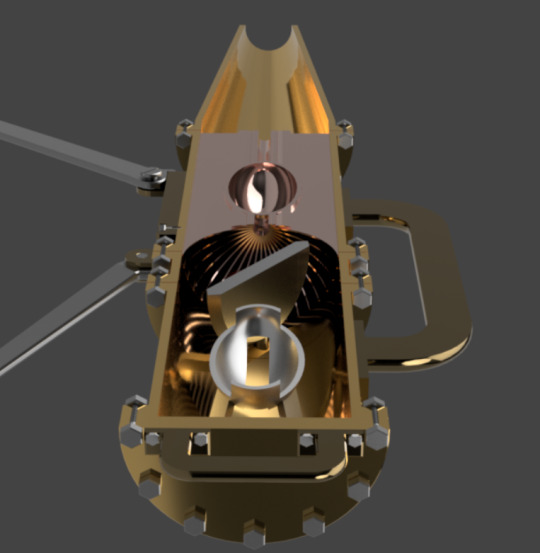

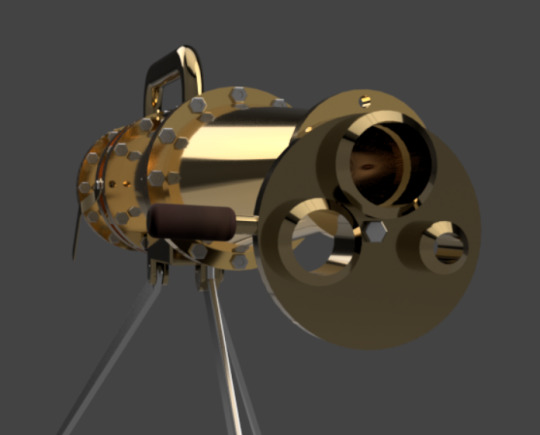

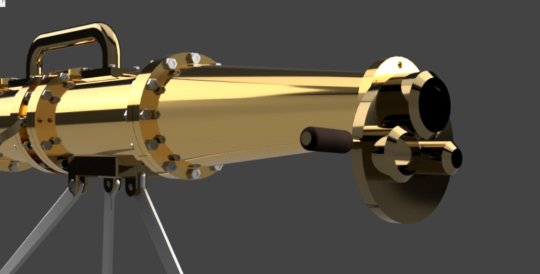

so, i turned to fusion360 to produce a feasible design for this nightmare contraption. as we had access to copper and bronze, i figured out that a simple tube shape with a conical nozzle could realistically withstand the heat and hold the steam pressure. one compartment holds the water rock, the other has a copper radiator with the heat stone inside of it. pull the lever, water contacts copper, water go whoosh and boom, steam cannon! for some unknown reason, i actually turned to thermodynamics and material science to figure out how thick the tubes should be. i suppose i was just taken by fey mood and went full turbonerd on this. ah well.

then, the first prototype was finished and rendered. after some back and forth, and quite a bit of negotiating with our DM (i'm really sorry for exposing you to my bullshit, Telen) we agreed that this could feasibly be produced within our setting. but something felt off. i was not quite satisfied with how it looked.

i carried on and added a collapsible tripod for easier deployment, and a handle on the top for better portability. (realistically, of course, this contraption would be awfully heavy, and only the strongest member of our party could carry it around. ah well). and finally, i had a stroke of inspiration. or maybe just a regular stroke. i though, what if we build up the pressure instead of just releasing it immediately? what if we somehow block the main nozzle for a while, and let it cook? the blast would be much stronger when you finally release it. and so -

the final version took form. i added a sliding attachment to the main nozzle that could block the output for a while (we figured it would be reasonable for it to take a full turn in combat to build up steam pressure), and then release it through one of the nozzles. and as the final stroke, i named this abomination - "Heated Exchange".

witness.

#3d model#dnd#steampunk#3d art#3d render#3d artwork#my project#d&d#fusion 360#contextless#metalwork#nerd shit#turbonerd

14 notes

·

View notes